Accessory Devices and Peripherals

Where standard machines are not right for the job, various aids are available to you for rationalisation of the work flow

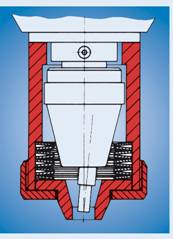

| 1 Taumel head = 2 cold-forming tools Changing the tool with the machine in operation without any hold-ups or down- time, which can be either integrated in the program or semi-automatic |

|

|

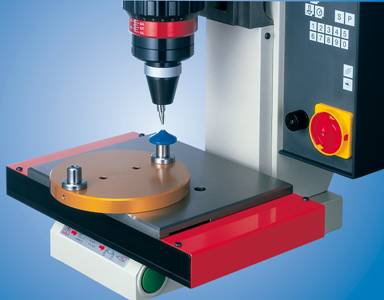

| Transfer plate 180° or indexing rotary plate with different divisions and diametral pitch of the workpiece that can be equipped with a component ejection mechanism |

|

|

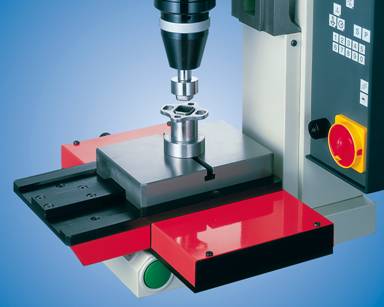

| Manual handling or pneumatic Slide table that can be fitted to all table and upright column machines |  |

|

| Simultaneous working of two riveting spots, which lie opposite each other |  |

|

| With the use of the BK Taumel tool, embossing and marking can be carried out as well as driven heads with contours on the outside, which are different from the normal round shape |  |

|

| Electronic depth stop with a detection device (for which a patent application has been applied), which can also be used as a Z axis |  |

|

| In cases that are few and far between, the riveting operations need a hold down for the workpieces. We build into all of our cold forming machines and units this type of device with a replaceable pressure plate. |  |